In the context of the continuously evolving global food industry, drying technologies have become a core factor in enhancing product value, extending shelf life, and meeting the growing demands of consumers. From freeze-dried foods to dried vegetables and convenient ready-to-eat meals, drying technology offers significant advantages.

In this article, we’ll explore popular drying methods—especially Freeze Drying, Air Drying, and Heat Pump Drying—and their applications in the food industry.

I. What Is Drying?

Drying is the process of removing water from food using heat, pressure, or other technical methods. This process aims to extend shelf life, reduce weight, and preserve food quality. Modern drying technologies help retain flavor, color, and nutrients, aligning with consumer demand for healthy, convenient foods.

Today, several drying technologies are applied, including freeze drying, air drying, and heat pump drying. Each has its own characteristics and is suited to specific product types and usage goals.

II. Overview of Popular Drying Methods

1. Freeze Drying Technology

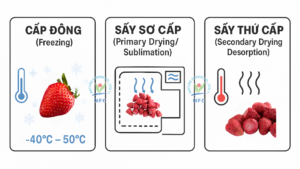

Freeze drying is one of the most advanced drying methods and is widely used for premium food production. The process involves three main steps:

-

Freezing: Food is frozen at extremely low temperatures (-30°C to -50°C), turning water molecules into a solid state.

-

Primary Drying (Sublimation): In a vacuum environment, ice turns directly into vapor, removing 90–95% of moisture.

-

Secondary Drying (Desorption): Remaining moisture is removed to reach a moisture content of 1–4%, ensuring long-term preservation without preservatives.

Benefits of Freeze Drying:

-

Nutrient Retention: Low-temperature drying preserves vitamins, enzymes, and proteins.

-

Flavor & Color: Maintains natural appearance and taste due to minimal cell structure damage.

-

Long Shelf Life: Freeze-dried foods can be stored for years without the need for preservatives.

-

Lightweight: Ideal for export, aerospace, and military applications.

-

Quick Rehydration: Easily restored to near-original state with added water.

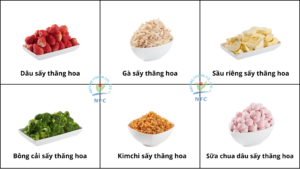

Applications of Freeze Drying in Food:

-

Dried fruits & vegetables: Strawberries, durian, jackfruit, etc.

-

Instant foods: Soups, coffee, noodles.

-

High-end products: Cordyceps, mushrooms, mangosteen, etc.

2. Air Drying Technology

Air drying is a traditional method that uses hot air to evaporate moisture from food. It’s a cost-effective, widely used approach suitable for various ingredients.

Key Features:

-

Hot air (50°C to 80°C) is applied in drying chambers or continuous drying systems.

-

Suitable for vegetables, fruits, and herbs.

Benefits:

-

Low Cost: Simple equipment, suitable for small to medium-sized businesses.

-

Easy Operation: Requires no complex technology.

-

High Volume Production: Ideal for items like sweet potato, carrot, and dried jackfruit.

Applications:

-

Dried vegetables: Onion, garlic, carrot, potato.

-

Dried fruits: Mango, banana, apple.

-

Spices & herbs: Ginger, turmeric, tea leaves.

Limitations:

-

Nutrient Loss: High temperatures can degrade vitamins and enzymes.

-

Texture Changes: May cause shrinkage or color loss.

3. Heat Pump Drying Technology

Heat pump drying uses low-temperature, low-humidity air (typically under 40°C) to dry food. This method is often paired with dehumidifiers for increased efficiency.

Features:

-

Suitable for sensitive ingredients.

-

Longer drying time, but better product quality.

-

Ideal for high-end or easily degradable foods.

Benefits:

-

Preserves Nutrition: Retains more vitamins and minerals.

-

Natural Flavor: Minimally alters taste and color.

-

Safe: Low temperature reduces fire/explosion risk.

Limitations:

-

High Cost: Requires specialized equipment and longer drying times.

-

Limited Capacity: Less suitable for mass production.

Applications:

-

Premium Foods: Freeze-dried strawberries, kiwi, nuts.

-

Herbal Ingredients: Ginseng, lingzhi mushrooms, medicinal herbs.

III. Comparison of Drying Technologies

| Method | Freeze Drying | Air Drying | Heat Pump Drying |

|---|---|---|---|

| Temperature | -30°C to -50°C | 50°C to 80°C | Under 40°C |

| Nutrient Retention | High | Low to Medium | Medium to High |

| Shelf Life | Very Long (Years) | Medium (6–12 months) | Long |

| Cost | High | Low | Medium |

| Applications | Premium, Export | Mass-market foods | Premium foods |

IV. Practical Applications in the Food Industry

1. Dried Vegetables and Fruits

Vegetables and fruits are common materials in dried food production. From snacks like dried jackfruit and mango to cooking ingredients such as garlic, turmeric, carrot, and cabbage, drying technologies have transformed agricultural products into high-value goods.

2. Dried Meat and Seafood

Thanks to modern drying tech, meats, fish, and shrimp are now processed at larger, more professional scales, enhancing value for farmers and processors alike.

3. Medicinal Herbs and Special Products

Modern drying preserves the bioactive compounds in medicinal herbs like cordyceps and ginseng, extending shelf life and maintaining potency.

4. Wider Applications

Drying is not limited to ingredients. It is also the foundation of many innovative consumer products. One notable example is its role in producing nutritious food for astronauts, which has evolved into today’s convenient freeze-dried foods.

Although freeze-dried foods have long been popular globally, in Vietnam, this technology remains relatively new due to high investment costs and complex operation requirements.

Typical examples include freeze-dried soups, noodles, and instant coffee. These are ideal for modern lifestyles, especially in tourism, military, and aerospace sectors.

In Vietnam, NFC Food Co., Ltd. has pioneered the adoption of freeze drying, launching groundbreaking products like:

-

I.SOUP: Instant freeze-dried soups with 14 flavors (7 vegetarian, 7 meat-based), ready in 3 minutes.

-

I.SOUP HUUPS!: Nutritious instant soups such as seafood or red apple chicken soup, perfect for busy people.

-

I.YAUA: Freeze-dried yogurt with probiotics, a healthy snack option.

V. NFC – A Trusted Food Drying Enterprise in Vietnam

NFC Food Co., Ltd. is a leading Vietnamese food drying company pioneering freeze-drying technology. Their factory is located in Nhon Trach 1 Industrial Park, Dong Nai Province.

NFC operates 5 freeze dryers with an annual capacity of ~4,000 tons of finished products. Their products not only serve the domestic market but are also exported to demanding regions like Japan, Korea, Australia, the U.S., and Singapore, affirming their quality and credibility.

Conclusion

Drying technologies—especially freeze drying and air drying—are ushering in a new era for the food industry. From nutrient retention and shelf life to product convenience, these methods meet rising consumer expectations. Led by trusted companies like NFC, Vietnam’s dried food sector is gradually conquering global markets, delivering sustainable value for agriculture and food processing.

Looking for high-quality freeze-dried food or a reliable partner?

Contact NFC Food Co., Ltd. today to explore modern and sustainable nutrition solutions!