In the context of the global food industry’s continuous search for solutions to optimize product quality and preservation, freeze-drying technology has emerged as a “game-changer,” particularly for agricultural products and premium foods. This process maximizes the retention of nutritional value, flavor, and natural color of food while extending shelf life without the need for chemical preservatives (Nowak et al. 2020).

I. What is Freeze-Drying?

Freeze-drying, also known as lyophilization, is one of the most advanced drying methods today. It involves freezing food at extremely low temperatures, typically between -30°C to -50°C, followed by sublimation of water molecules in a low-pressure environment.

This process allows water to transition directly from a solid (ice) to a gas, enabling the food to retain its original shape during drying. Additionally, the structure, nutrients, color, and flavor remain largely intact for extended periods without the need for preservatives.

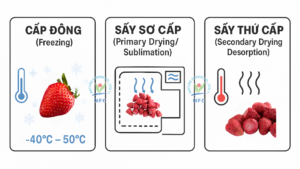

II. Three Basic Steps of the Freeze-Drying Process

1. Freezing: The product is rapidly frozen to deep sub-zero temperatures (-40°C to -50°C), ensuring all water molecules in the food turn into ice crystals.

2. Primary Drying (Sublimation): The pressure in the drying chamber is reduced to a deep vacuum, and a small amount of heat is applied to allow water to transition from solid to gas, which is then extracted by a condensation system. This stage removes approximately 90-95% of the water content.

3. Secondary Drying (Desorption): The temperature is slightly increased to remove residual moisture, reducing the product’s moisture content to a very low level (typically 1-4%).

III. Six Benefits of Freeze-Drying Technology

– Maximum Nutrient Retention: The low-temperature process preserves vitamins, enzymes, proteins, and heat-sensitive compounds almost entirely.

– Retention of Natural Flavor and Color: Minimal damage to cellular structure ensures the product retains its original taste and vibrant color.

– Extended Shelf Life: Extremely low moisture content inhibits microbial and enzymatic activity, allowing products to be stored for years without preservatives.

– Preservation of Shape and Structure: Freeze-dried products are porous, crisp, lightweight, and maintain their original form without shrinking or deforming. They can quickly rehydrate to near their original state when soaked in water.

– Lightweight and Convenient: With nearly all water removed, products are extremely light, reducing transportation costs and requiring no special storage conditions (only airtight packaging is needed).

– Versatile Applications: Suitable for a wide range of food products, from fruits and vegetables to premium ingredients like cordyceps and mushrooms.

V. Applications in the Food Industry

Freeze-drying technology is increasingly applied in the food industry due to its ability to preserve nutrients, extend shelf life, and maintain flavor, paving the way for innovative processing of agricultural products and premium foods.

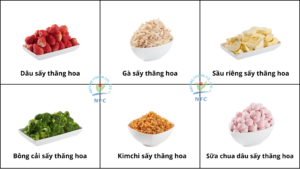

– Fruits and Vegetables: Strawberries, jackfruit, durian, dragon fruit, kale, etc., retain their color, flavor, and nutrients, transforming into high-value snacks. Freeze-drying is also used for premium ingredients like cordyceps and mushrooms for value-added products.

– Instant Foods: High-end instant coffee, instant soups, noodles, and convenient foods for astronauts and military use.

– Seafood and Meat: Shrimp, fish, and beef retain natural flavors and are easy to reprocess.

– Yogurt, Ice Cream, and Dairy Products: Create unique snacks while preserving beneficial probiotics.

– Herbs and Floral Teas: Preserve valuable bioactive compounds in medicinal herbs and tea flowers.

VI. NFC’s Innovative Application of Freeze-Drying Technology in Food Production

NFC is a pioneering enterprise in Vietnam’s freeze-dried food sector, with a commitment to integrating advanced technology into its production and processing from the outset.

Notably, Nature Foods Company Ltd. leads the way in applying freeze-drying technology in Vietnam. Its factory, located in Nhon Trach 1 Industrial Park, Phuoc Thien Commune, Nhon Trach District, Dong Nai Province, is equipped with five freeze-drying (FD) machines, boasting an annual production capacity of approximately 4,000 tons of finished products.

With advanced freeze-drying technology, NFC has successfully launched innovative product lines that have made a significant impact on the market. Key products include:

– I.SOUP Instant Freeze-Dried Soup: Offering 14 diverse soup varieties inspired by Vietnamese flavors, including 7 vegetarian and 7 non-vegetarian options. Simply add hot water for 3 minutes to enjoy a bowl of flavorful soup with fresh vegetables, as if home-cooked.

– I.SOUP HUUPS! freeze-dried instant soup: A line of freeze-dried nutritional soups with six options, such as Seafood Soup, Chicken and Red Date Soup, and Salmon Soup, featuring real toppings. These are quick, nutrient-packed meals ideal for busy individuals needing convenient yet wholesome food.

– I.YAUA Freeze-Dried Yogurt: A probiotic-rich snack that’s both delicious and beneficial for digestion.

All products are developed by NFC Co., Ltd. with a spirit of innovation and a commitment to delivering convenient, healthy, and natural food solutions to consumers in Vietnam and worldwide.